Automated calculation for turning parts and milling parts

With Spanflug MAKE you calculate manufacturing times and quote prices automatically on the basis of CAD models and drawings. All parameters relevant to manufacturing are automatically evaluated. No manual input is required. Within a few seconds, you will receive a detailed calculation proposal that shows, for example, material costs, set-up costs and manufacturing costs. This saves you a lot of time and enables you to calculate precise, reproducible prices.

This is how you benefit from automated calculation

- Save valuable time and respond faster to customer inquiries.

- Reduce the cost of quoting.

- Optimize the hit rate of your quotes with prices in line with the market.

- Relieve your technical staff of administrative tasks to fully focus on manufacturing.

- Get started immediately, with no data set, configuration, or high initial investment.

Calculating turning parts and milling parts with Spanflug is so easy

As a registered user, you can get started right away. Simply upload the CAD model and the drawing of the part to be calculated, select the quantity and you will receive a detailed calculation proposal within a few seconds. Try it out right away.

You can calculate up to 5 parts per month permanently free of charge. Watch our demo video to see how it works and how easy quote calculation can be.

Our manufacturing processes

Turning

Turned parts up to a diameter of 1,000 mm and a length of 6,000 mm

Milling

Milling parts up to 6,000 mm x 2,000 mm x 350 mm

Grinding

External cylindrical and surface grinding

Flexible stock selection

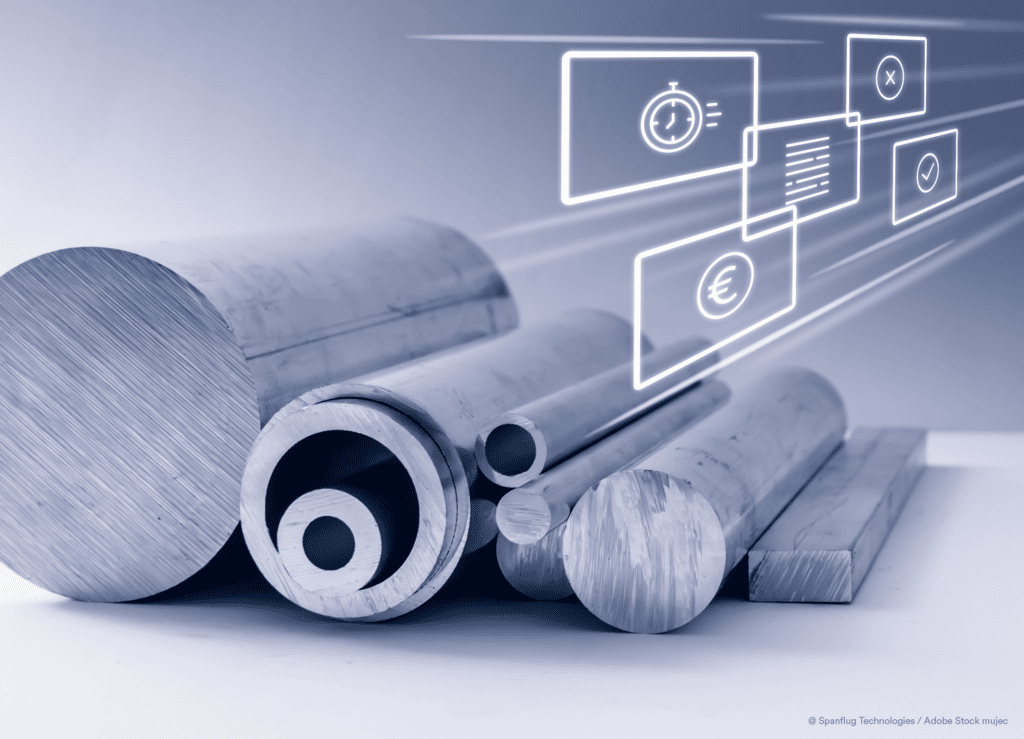

Standard stocks with real-time prices

Our standard database includes stocks made from more than 60 different materials. Spanflug MAKE uses daily updated prices from connected stock suppliers for the calculation. This allows you to calculate precise, market-driven prices, save time-consuming inquiries to material suppliers and achieve the calculated margins even when prices fluctuate.

As soon as the order for the quoted parts comes in, you can source the needed stocks quickly and easily via Spanflug.

>> Stock procurement with Spanflug MAKE

Near-net-shape stocks

You can select near-net-shape stocks such as cast parts, laser parts or 3D printed parts as stock and take them into account in the calculation for resource-saving and economical manufacturing.

Laser, flame and water jet cutting

You can select contour cuts such as laser, flame or water jet cuts as a stock shape and include these in the calculation.

.

.

Calculate post-treatments

In Spanflug MAKE you have over 30 post-treatment processes available for calculation. You can choose from a wide range of heat and surface treatments and coatings.

You can see which post-treatments are available for the part to be calculated by selecting the material. There you can also see which treatment processes can be combined with each other.

Optimize and individualize the calculation results for your company

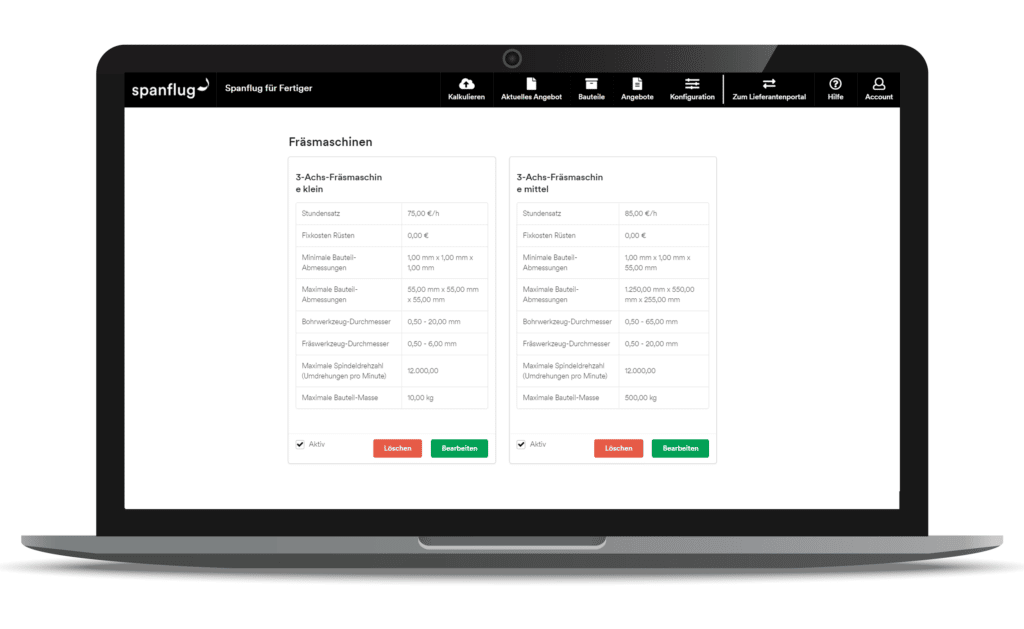

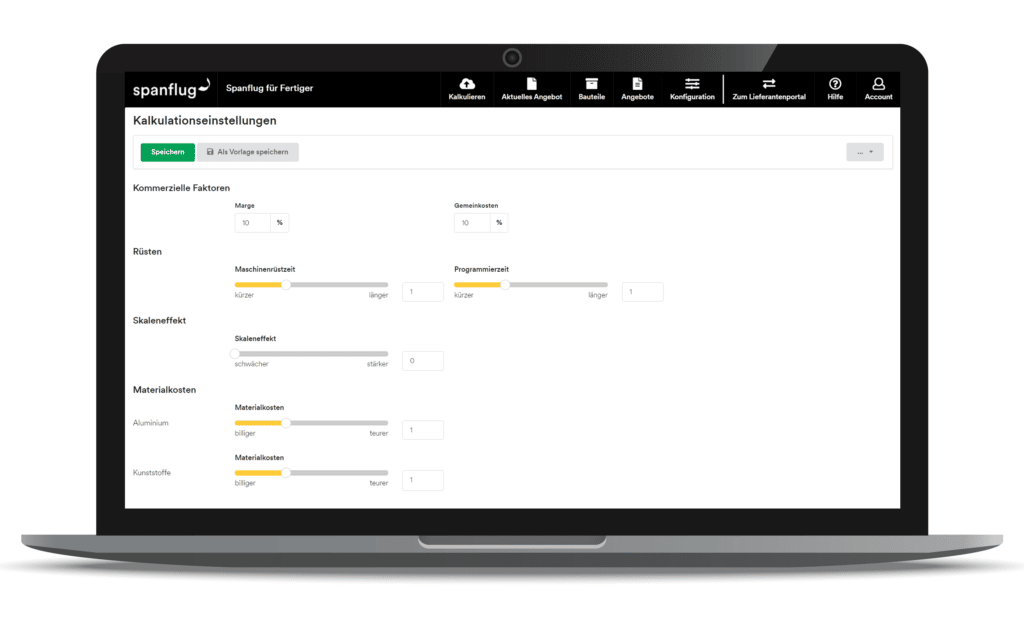

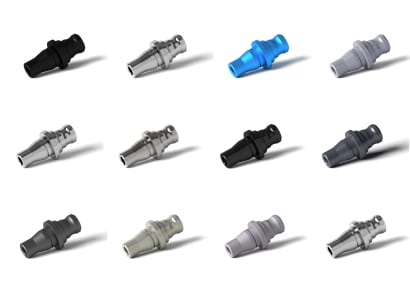

You have the possibility to create your individual CNC machines for turning and milling in your account at Spanflug MAKE and thus finetune the price calculation to your business. You can also use the software with the Spanflug default machine tools having to make individual configurations.

In addition to the machine park, you can customize the following calculation settings for your machine shop:

- Cutting values

- Material cost

- Set-up costs

- Margin

- Overhead costs

Discover the other functions of Spanflug MAKE

Quote preparation

Manage inquiries and customer master data and create quotes as PDF with just a few clicks.

>> More Info

Increase sales

As a manufacturing partner at Spanflug, you receive orders that match your expertise – entirely without the need to prepare any quotes.

>> More Info

Work preparation

Spanflug MAKE is your digital colleague in work preparation and supports you in procurement.

>> More Info